Back مادة مؤلفة Arabic Kompozit material Azerbaijani Композитен материал Bulgarian Compòsit Catalan Kompozitní materiál Czech Defnydd cyfansawdd Welsh Komposit Danish Verbundwerkstoff German Kompozita materialo Esperanto Material compuesto Spanish

It has been suggested that this article be split into articles titled Autoclave moulding, Resin transfer moulding, Pressure bag moulding and Light resin transfer moulding. (discuss) (November 2020) |

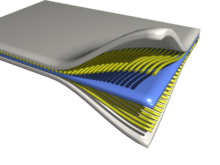

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials.[1] These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called composite laminates.

Typical engineered composite materials are made up of a binding agent forming the matrix and a filler material (particulates or fibres) giving substance, e.g.:

- Concrete, reinforced concrete and masonry with cement, lime or mortar (which is itself a composite material) as a binder

- Composite wood such as glulam and plywood with wood glue as a binder

- Reinforced plastics, such as fiberglass and fibre-reinforced polymer with resin or thermoplastics as a binder

- Ceramic matrix composites (composite ceramic and metal matrices)

- Metal matrix composites[2]

- advanced composite materials, often first developed for spacecraft and aircraft applications.

Composite materials can be less expensive, lighter, stronger or more durable than common materials. Some are inspired by biological structures found in plants and animals.[3] Robotic materials are composites that include sensing, actuation, computation, and communication components.[4][5]

Composite materials are used for construction and technical structures such as boat hulls, swimming pool panels, racing car bodies, shower stalls, bathtubs, storage tanks, imitation granite, and cultured marble sinks and countertops.[6][7] They are also being increasingly used in general automotive applications.[8]

- ^ "What are Composites". Discover Composites. Archived from the original on 2021-05-22. Retrieved 2020-12-18.

- ^ Zhou, M.Y.; Ren, L.B.; Fan, L.L.; Zhang, Y.W.X.; Lu, T.H.; Quan, G.F.; Gupta, M. (October 2020). "Progress in research on hybrid metal matrix composites". Journal of Alloys and Compounds. 838: 155274. doi:10.1016/j.jallcom.2020.155274.

- ^ Nepal, Dhriti; Kang, Saewon; Adstedt, Katarina M.; Kanhaiya, Krishan; Bockstaller, Michael R.; Brinson, L. Catherine; Buehler, Markus J.; Coveney, Peter V.; Dayal, Kaushik; El-Awady, Jaafar A.; Henderson, Luke C.; Kaplan, David L.; Keten, Sinan; Kotov, Nicholas A.; Schatz, George C.; Vignolini, Silvia; Vollrath, Fritz; Wang, Yusu; Yakobson, Boris I.; Tsukruk, Vladimir V.; Heinz, Hendrik (January 2023). "Hierarchically structured bioinspired nanocomposites". Nature Materials. 22 (1): 18–35. Bibcode:2023NatMa..22...18N. doi:10.1038/s41563-022-01384-1. PMID 36446962.

- ^ McEvoy, M. A.; Correll, N. (19 March 2015). "Materials that couple sensing, actuation, computation, and communication". Science. 347 (6228): 1261689. Bibcode:2015Sci...34761689M. doi:10.1126/science.1261689. PMID 25792332.

- ^ "Autonomous Materials Will Let Future Robots Change Color And Shift Shape". popsci.com. 20 March 2015. Archived from the original on 27 September 2017. Retrieved 3 May 2018.

- ^ "Composites | Composite Materials". Mar-Bal, Inc. 2013-10-15. Archived from the original on 2015-11-13. Retrieved 2020-12-18.

- ^ "Applications | Composites UK". compositesuk.co.uk. Archived from the original on 2015-02-26. Retrieved 2020-12-18.

- ^ "Achieving Class A Appearance On Fiber-Reinforced Substrates". www.coatingstech-digital.org. Archived from the original on 2021-09-20. Retrieved 2021-06-24.