Back Asphalt#Splittmastixasphalt German Steenmastiekasfalt Dutch Mastyks grysowy SMA Polish Щебёночно-мастичный асфальтобетон Russian 沥青玛𤧛脂碎石 Chinese

Stone mastic asphalt (SMA), also called stone-matrix asphalt, was developed in Germany in the 1960s with the first SMA pavements being placed in 1968 near Kiel.[1] It provides a deformation-resistant, durable surfacing material, suitable for heavily trafficked roads. SMA has found use in Europe, Australia, the United States, and Canada as a durable asphalt surfacing option for residential streets and highways. SMA has a high coarse aggregate content that interlocks to form a stone skeleton that resists permanent deformation. The stone skeleton is filled with a mastic of bitumen and filler to which fibres are added to provide adequate stability of bitumen and to prevent drainage of binder during transport and placement. Typical SMA composition consists of 70−80% coarse aggregate, 8−12% filler, 6.0−7.0% binder, and 0.3 per cent fibre.

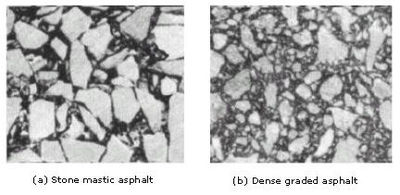

The deformation resistant capacity of SMA stems from a coarse stone skeleton providing more stone-on-stone contact than with conventional dense graded asphalt (DGA) mixes (see above picture). Improved binder durability is a result of higher bitumen content, a thicker bitumen film, and lower air voids content. This high bitumen content also improves flexibility. Addition of a small quantity of cellulose or mineral fibre prevents drainage of bitumen during transport and placement. There are no precise design guidelines for SMA mixes available in Europe. The essential features, which are the coarse aggregate skeleton and mastic composition, and the consequent surface texture and mixture stability, are largely determined by the selection of aggregate grading and the type and proportion of filler and binder. In the US, detailed mix design guidelines have been developed for SMA and published by the US National Asphalt Pavement Association in their Quality Improvement Publication QIP 122 as given in the references.

- ^ Waanders, G.; Els, H. (1995). "Splittmastixasphalt und Dränasphalt in den Niederlanden. Erfahrungen und Untersuchungen in der Provinz Overijsel". Asphalt. 95 (4): 8–17.