Back تصلد بارد Arabic Kaltumformung German Ενδοτράχυνση Greek Plidurigo Esperanto Endurecimiento por deformación Spanish Kalestumine Estonian افزایش سختی کرنشی Persian Metallin kylmämuokkaus Finnish Écrouissage French Saotharchruachan Irish

This article needs additional citations for verification. (September 2020) |

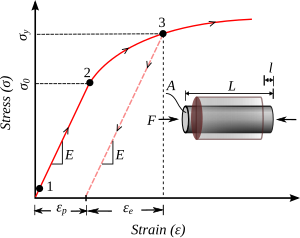

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials.[1] Work hardening may be desirable, undesirable, or inconsequential, depending on the application.

This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material.[2] Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion.[3] Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium,[4] however others can be strengthened only via work hardening, such as pure copper and aluminum.[5]

- ^ Scales, M.; Kornuta, J.A.; Switzner, N.; Veloo, P. (December 1, 2023). "Automated Calculation of Strain Hardening Parameters from Tensile Stress vs. Strain Data for Low Carbon Steel Exhibiting Yield Point Elongation". Experimental Techniques. 47 (6): 1311–1322. doi:10.1007/s40799-023-00626-4. ISSN 1747-1567.

- ^ Degarmo, Black & Kohser 2003, p. 60.

- ^ Van Melick, H. G. H.; Govaert, L. E.; Meijer, H. E. H. (2003), "On the origin of strain hardening in glassy polymers", Polymer, 44 (8): 2493–2502, doi:10.1016/s0032-3861(03)00112-5

- ^ Swenson, C. A. (1955), "Properties of Indium and Thallium at low temperatures", Physical Review, 100 (6): 1607–1614, Bibcode:1955PhRv..100.1607S, doi:10.1103/physrev.100.1607

- ^ Smith & Hashemi 2006, p. 246.